In today’s highly competitive business environment, efficiency and value creation are critical for sustained success. Lean operations, a methodology rooted in eliminating waste and maximizing value, has emerged as a cornerstone for achieving these goals. But how does the adoption of lean principles revolutionize operations, and why is it so vital for modern businesses?

What Are Lean Operations?

Lean operations focus on delivering maximum value to customers with minimal resources. This approach, inspired by the Toyota Production System, emphasizes continuous improvement and waste elimination across all processes. The goal is to streamline workflows, enhance productivity, and ensure that every activity adds value from the customer’s perspective.

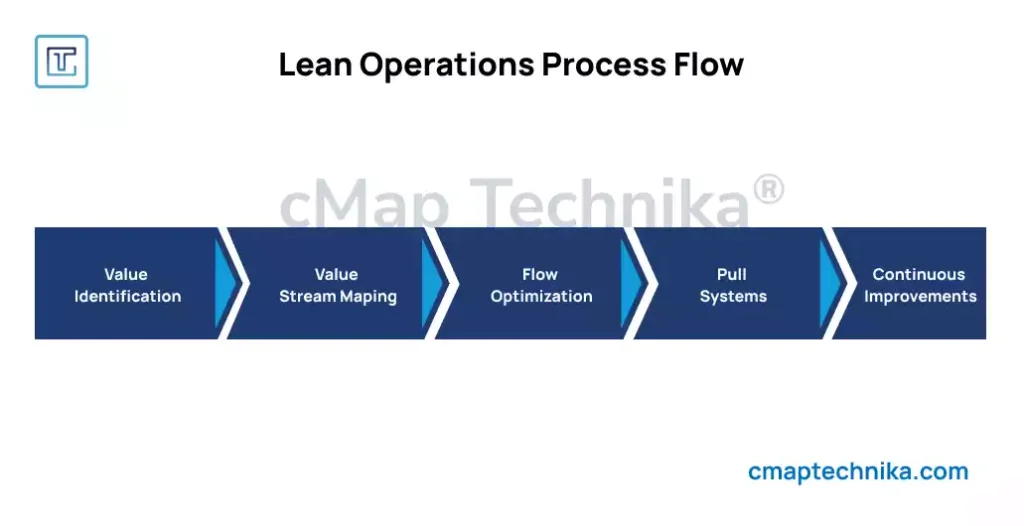

The five core principles of lean operations are:

- Value Identification: Determining what the customer truly values.

- Value Stream Mapping: Analyzing the steps required to deliver value and identifying non-value-adding activities.

- Flow Optimization: Ensuring that processes flow seamlessly without interruptions.

- Pull Systems: Producing only what is needed when it is needed, reducing excess inventory.

- Continuous Improvement: Regularly reviewing and refining processes to eliminate inefficiencies.

The Pillars of Lean Operations

To successfully implement lean operations, organizations must focus on:

1. Waste Elimination (Muda)

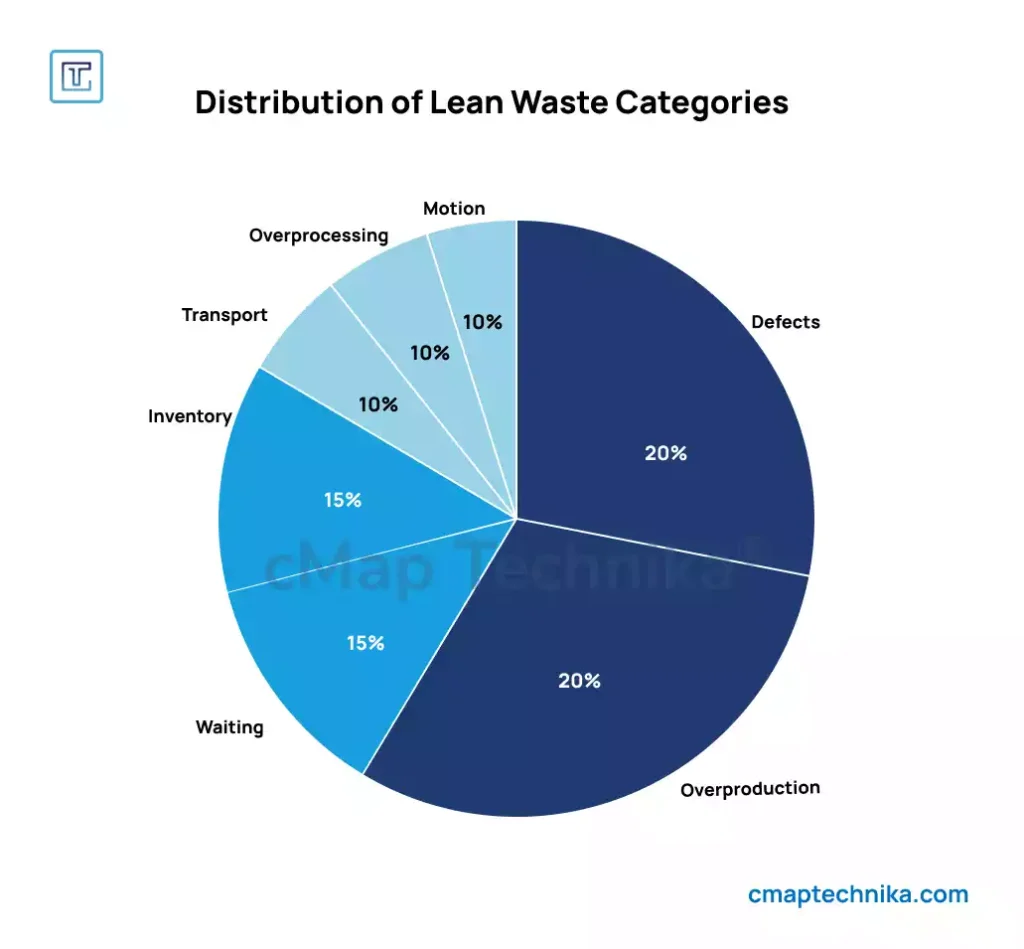

Lean principles categorize waste into seven types:

- Overproduction: Producing more than needed.

- Waiting: Idle time during processes.

- Transport: Unnecessary movement of materials.

- Overprocessing: Performing redundant or excessive tasks.

- Inventory: Excess materials or products.

- Motion: Unnecessary movement by people.

- Defects: Errors requiring rework or scrapping.

By identifying and addressing these inefficiencies, businesses can significantly improve operational efficiency.

2. Customer-Centric Value Creation

Lean operations prioritize activities that directly contribute to customer satisfaction. For example, a furniture manufacturer may focus on reducing delivery times and ensuring product durability—attributes that customers value highly.

3. Empowered Workforce

Lean operations encourage employees to actively participate in identifying and solving inefficiencies. Tools like Kaizen (continuous improvement) foster a culture of collaboration and innovation.

4. Standardization and Simplicity

Standardized processes reduce variability and simplify workflows, making it easier to maintain quality and efficiency.

Benefits of Lean Operations

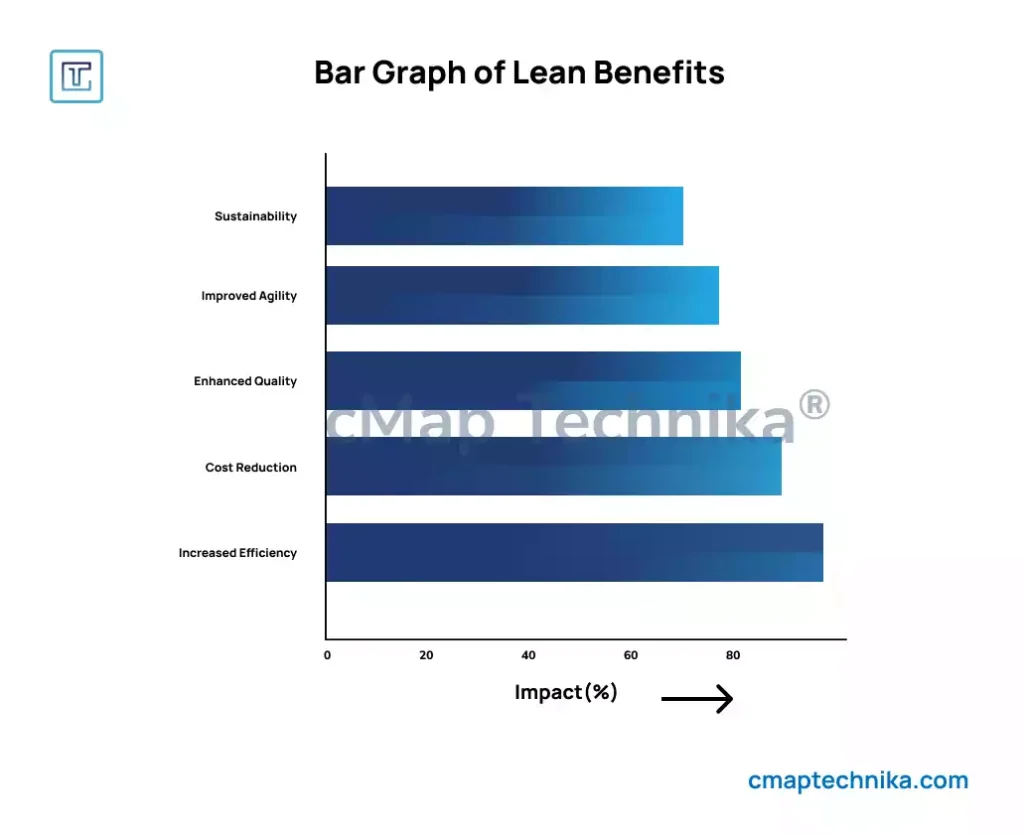

The adoption of lean principles yields numerous advantages:

- Increased Efficiency: Streamlined processes ensure optimal use of time, labor, and resources.

- Cost Reduction: Eliminating waste directly lowers operational expenses.

- Enhanced Quality: Consistent processes lead to fewer defects and higher product reliability.

- Improved Agility: Lean operations enable businesses to respond swiftly to market changes and customer demands.

- Sustainability: Reducing waste contributes to environmental sustainability and aligns with corporate social responsibility goals.

Lean Operations in Action

Lean operations have become a cornerstone of modern business strategy, enabling companies to enhance efficiency, reduce waste, and deliver higher value to customers. The success of lean principles is evident across various industries, where companies have adopted systematic approaches to streamline production, improve supply chains, and respond quickly to changing market demands.

Case Study 1: Toyota – The Origin of Lean Production

Toyota’s lean production system, known as the Toyota Production System (TPS), is widely regarded as the foundation of lean manufacturing. Introduced in the 1950s by Taiichi Ohno and Eiji Toyoda, TPS revolutionized the automotive industry by focusing on two key principles:

- Just-in-Time (JIT): Toyota produces only what is needed, when it is needed, and in the amount needed. This minimizes inventory costs and reduces waste.

- Kaizen (Continuous Improvement): Employees at all levels are encouraged to identify inefficiencies and suggest improvements, creating a culture of ongoing optimization.

For example, Toyota’s Kanban system—a visual scheduling tool—enabled the company to align production schedules with real-time demand. In the 1970s, this approach helped Toyota outperform U.S. automakers by improving production efficiency and reducing defects. The company’s ability to quickly identify and eliminate waste allowed it to maintain cost leadership without compromising on quality. Today, TPS remains a benchmark for operational excellence, influencing industries beyond automotive, including healthcare and manufacturing.

Case Study 2: Amazon – Lean Principles in Supply Chain Management

Amazon has successfully adapted lean principles to its supply chain and logistics operations, becoming a global leader in e-commerce and order fulfillment. Amazon’s approach to lean operations includes:

- Automated Warehousing: Amazon’s fulfillment centers leverage robotics and AI to automate picking, packing, and sorting processes. This reduces human error and increases efficiency.

- Predictive Analytics: Amazon uses machine learning to anticipate customer demand, enabling more accurate inventory management and minimizing stockouts or overstocking.

- Optimized Last-Mile Delivery: Through investments in delivery infrastructure and third-party logistics partnerships, Amazon ensures fast, reliable, and cost-effective last-mile delivery.

A notable example is the development of Amazon Prime, which guarantees two-day (or faster) delivery. This required Amazon to overhaul its logistics network, incorporating real-time tracking, automated warehouse operations, and advanced routing algorithms. The result is a highly efficient supply chain that delivers over 1.5 million packages per day while keeping operational costs competitive.

Case Study 3: Zara – Fast Fashion Through Lean Inventory

Zara, the global fashion retailer, applies lean principles to its production and supply chain strategy to respond rapidly to shifting fashion trends. Unlike traditional retailers that rely on long production cycles, Zara follows a short-cycle production model that enables it to bring new designs to market within two to three weeks.

- Demand-Driven Inventory: Zara produces in small batches and monitors store-level sales data to adjust production quickly based on real-time customer demand.

- Localized Manufacturing: By keeping production close to its headquarters in Spain, Zara reduces lead times and increases the flexibility to respond to changing fashion trends.

- Lean Inventory Management: Zara limits overproduction and markdowns by maintaining tight control over inventory levels, ensuring high turnover and minimal waste.

This lean model has allowed Zara to maintain profitability even in competitive retail markets while reducing waste and improving customer satisfaction through faster product availability.

Implementing Lean Operations

Organizations seeking to adopt lean principles should follow these steps:

- Conduct a Waste Audit: Identify inefficiencies and categorize them according to the seven types of waste.

- Engage Stakeholders: Involve employees at all levels to foster a culture of lean thinking.

- Map the Value Stream: Analyze the end-to-end process to identify value-adding and non-value-adding steps.

- Prioritize Improvements: Focus on high-impact areas that deliver immediate results.

- Monitor and Refine: Regularly review processes and incorporate feedback for ongoing optimization.

Challenges in Lean Implementation

While lean operations offer significant benefits, their implementation presents several hurdles that can undermine success if not carefully managed. Successful lean adoption requires not only process changes but also a shift in organizational culture and mindset. Overcoming these challenges is essential to achieving long-term efficiency and operational excellence.

1. Resistance to Change

One of the most common barriers to lean implementation is employee resistance to change. Lean principles often require employees to alter long-standing workflows, adopt new technologies, and embrace a culture of continuous improvement.

- Cultural Inertia: Employees accustomed to traditional hierarchies and fixed processes may perceive lean practices as disruptive or threatening to job security.

- Lack of Buy-In: Without clear communication about the benefits of lean operations, employees may view the changes as management-driven cost-cutting rather than a strategy for growth and improvement.

Example: When General Motors attempted to implement lean manufacturing practices in the 1980s, resistance from unionized workers and middle management slowed progress. By contrast, Toyota’s success with lean was largely due to its emphasis on employee involvement and training, which fostered a sense of ownership and trust.

Solution: To address resistance, businesses should involve employees early in the transition, provide clear training, and establish open communication channels to encourage feedback and adaptation.

2. High Initial Investment

Implementing lean operations often requires significant upfront costs related to training, process redesign, and technological upgrades. While lean principles focus on cost reduction over time, the initial financial outlay can be a barrier for businesses with limited capital.

- Training Costs: Employees must be trained in lean methodologies such as value stream mapping, just-in-time production, and root cause analysis.

- Technology Investment: Automation, AI-driven analytics, and supply chain optimization tools may require substantial capital expenditure.

Example: Boeing faced significant upfront costs when adopting lean manufacturing for its 787 Dreamliner program. The company had to redesign production processes and invest heavily in supply chain management technology. While the initial investment was high, the improved efficiency and faster production cycles eventually increased profitability.

Solution: Businesses can mitigate financial strain by adopting a phased approach, starting with pilot projects to demonstrate ROI before scaling lean initiatives company-wide.

3. Sustaining Momentum and Engagement

Lean operations are not one-time projects—they require ongoing effort and commitment to maintain momentum. Without continuous monitoring and improvement, businesses risk reverting to old inefficiencies.

- Lack of Leadership Commitment: Lean success depends on top-down support from executives and managers who actively promote and reinforce lean behaviors.

- Employee Fatigue: If lean practices are viewed as additional work rather than value-driven improvements, employees may disengage over time.

Example: After initial success with lean practices, healthcare provider Virginia Mason Medical Center struggled to maintain momentum when leadership turnover weakened institutional support for lean initiatives. Renewed focus on leadership training and employee engagement helped the organization reestablish lean as a core operational strategy.

Solution: Establish regular performance reviews, reinforce lean training programs, and align employee incentives with lean outcomes to maintain long-term commitment and engagement.

The Future of Lean Operations

Lean principles are evolving with the rise of Industry 4.0, where AI, IoT, and data analytics are enhancing efficiency and responsiveness. AI-driven optimization allows businesses to automate production adjustments and predict bottlenecks, improving overall efficiency. IoT sensors provide real-time monitoring of machine performance, enabling predictive maintenance and minimizing downtime. Data-driven decision-making is improving demand forecasting and inventory management, helping businesses reduce waste and streamline operations. Additionally, cloud-based platforms and automation tools are simplifying process mapping and performance tracking, ensuring that lean operations remain agile, cost-effective, and scalable in a rapidly changing business landscape.