In today’s dynamic business landscape, automation has emerged as a pivotal force driving operational excellence. By streamlining processes, reducing manual intervention, and enhancing consistency, automation lays the groundwork for scalability and long-term growth. But how exactly does automation transform operations, and what steps can businesses take to harness its full potential?

The Role of Automation in Operational Excellence

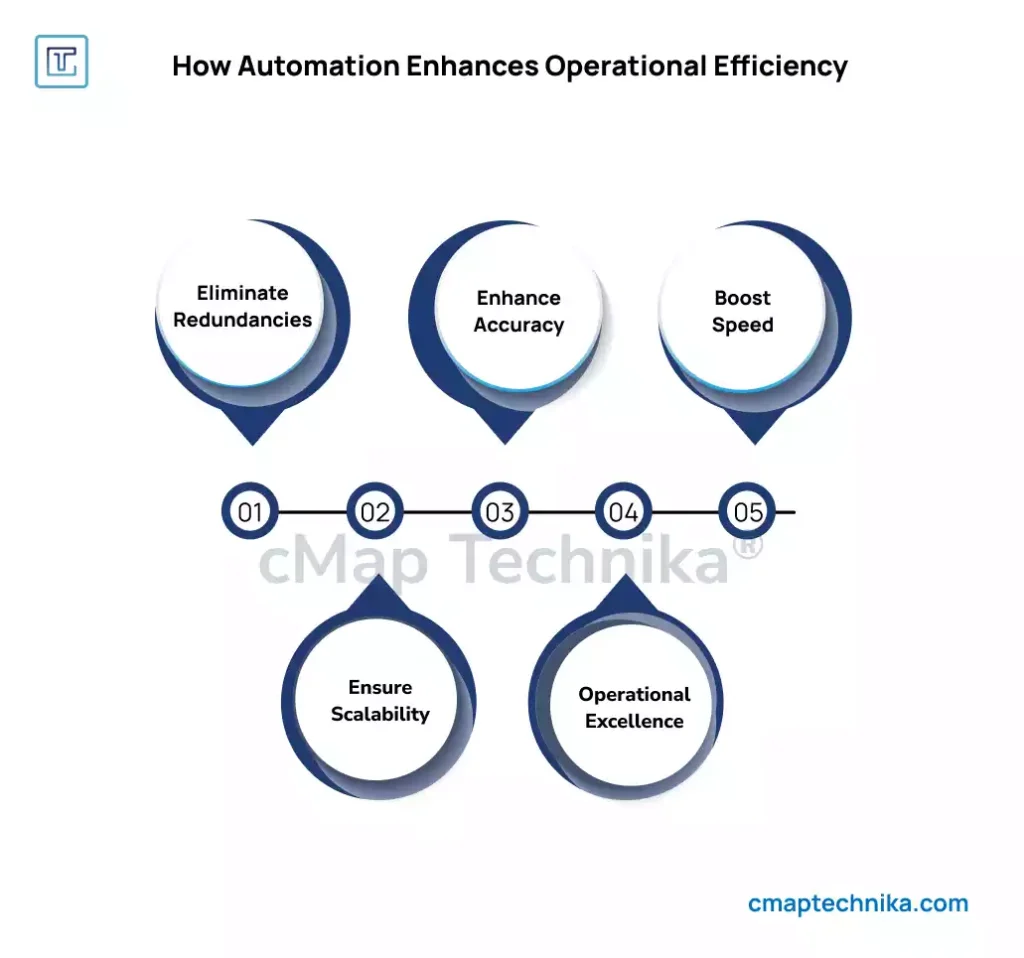

Automation refers to the use of technology to perform tasks with minimal human intervention. Its integration into operational workflows helps organizations achieve higher levels of efficiency, accuracy, and adaptability. Automation enables businesses to:

- Eliminate Redundancies: Automating repetitive tasks frees up resources for higher-value activities.

- Enhance Accuracy: Machines and software reduce human errors, ensuring consistent outcomes.

- Boost Speed: Automated processes work faster than manual methods, accelerating turnaround times.

- Ensure Scalability: Automation can handle increased workloads without a proportional increase in resources.

The Pillars of Scalable Automation

For automation to truly drive operational excellence, it must be built on a solid foundation. The key pillars include:

- Strategic Planning Automation efforts should align with organizational goals. This involves identifying critical processes that would benefit most from automation, such as supply chain management, customer service, or financial reporting.

- Technology Integration The integration of advanced technologies—including Artificial Intelligence (AI), Robotic Process Automation (RPA), and Internet of Things (IoT)—is essential for achieving scalability. AI-powered systems can analyze vast amounts of data, while IoT devices provide real-time insights into operations.

- Workforce Collaboration Automation should complement human efforts rather than replace them. By automating mundane tasks, employees can focus on strategic, creative, and decision-making responsibilities.

- Continuous Improvement Automation is not a one-and-done solution. Businesses must regularly review and refine automated processes to adapt to changing demands and emerging technologies.

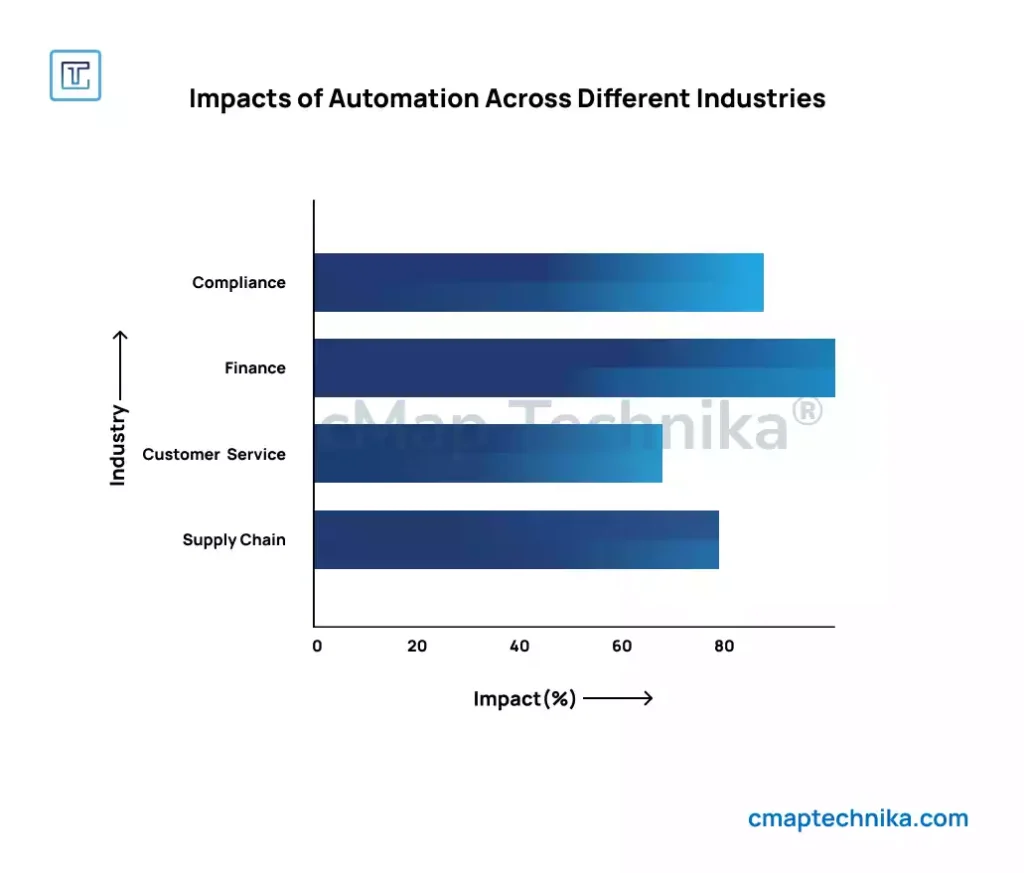

Transformative Impacts of Automation

The integration of automation drives transformative changes across various facets of operations:

1. Streamlined Supply Chain

Automation optimizes supply chain operations by:

- Automating inventory management through IoT-enabled systems.

- Predicting demand using AI-powered analytics.

- Enhancing logistics with autonomous vehicles and drones.

For instance, Amazon’s warehouses use automated robots to streamline order picking and packing, reducing delivery times and operational costs.

2. Enhanced Customer Service

Automation tools like chatbots and AI-powered CRM systems provide instant, accurate responses to customer queries. This ensures consistent service quality and enhances customer satisfaction. For example, Sephora’s chatbot assists customers with product recommendations, driving personalized experiences.

3. Efficient Financial Operations

RPA has revolutionized financial processes by automating tasks such as:

- Invoice processing.

- Expense reporting.

- Fraud detection.

This not only reduces errors but also provides real-time financial insights, aiding strategic decision-making.

4. Improved Compliance and Risk Management

Automated compliance systems ensure adherence to regulatory standards by:

- Monitoring activities for potential violations.

- Generating audit trails.

- Alerting organizations to risks in real-time.

Industries like healthcare and finance have greatly benefited from automation to maintain stringent compliance standards.

Steps to Integrate Automation Successfully

To fully realize the benefits of automation, organizations should follow these steps:

- Assess Current Processes: Conduct a thorough audit of existing workflows to identify inefficiencies and automation opportunities.

- Select the Right Tools: Choose technologies that align with operational needs and future scalability.

- Engage Stakeholders: Involve employees and stakeholders in the automation journey to foster collaboration and acceptance.

- Pilot and Refine: Start with pilot projects to test automation’s effectiveness, making adjustments as needed before full-scale implementation.

- Measure Impact: Use metrics like efficiency gains, cost savings, and error reduction to evaluate the success of automation efforts.

Real-World Examples

- Tesla: The company’s Gigafactories use automation extensively to manufacture electric vehicles, enabling high production volumes while maintaining quality.

- Procter & Gamble: By implementing automated data analysis tools, P&G streamlined its supply chain, reducing costs and improving delivery times.

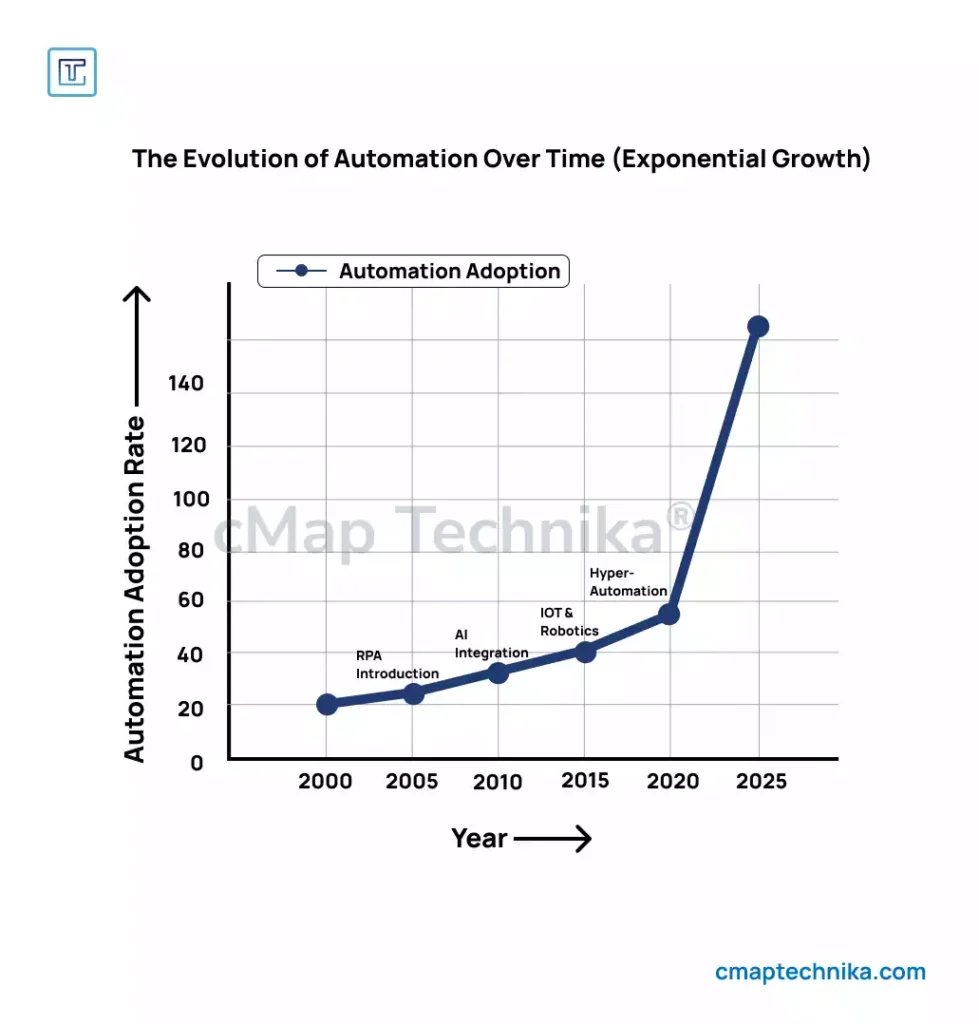

The Future of Automation in Operational Excellence

As automation technologies continue to evolve, their potential to shape operational excellence will grow exponentially. Emerging trends like hyper automation—which combines AI, RPA, and machine learning—promise to automate increasingly complex processes. Additionally, the integration of blockchain technology offers enhanced transparency and security in automated workflows.

Conclusion

Integrating automation into operational processes is no longer optional; it is imperative for scalability and consistency. By embracing automation strategically, businesses can unlock unprecedented levels of efficiency and innovation, positioning themselves for sustainable growth in an increasingly competitive landscape. The journey toward operational excellence begins with a commitment to harness the transformative power of automation.