Exploring how AI-driven predictive maintenance, process automation, and quality control are reshaping manufacturing efficiency and reducing downtime

Introduction

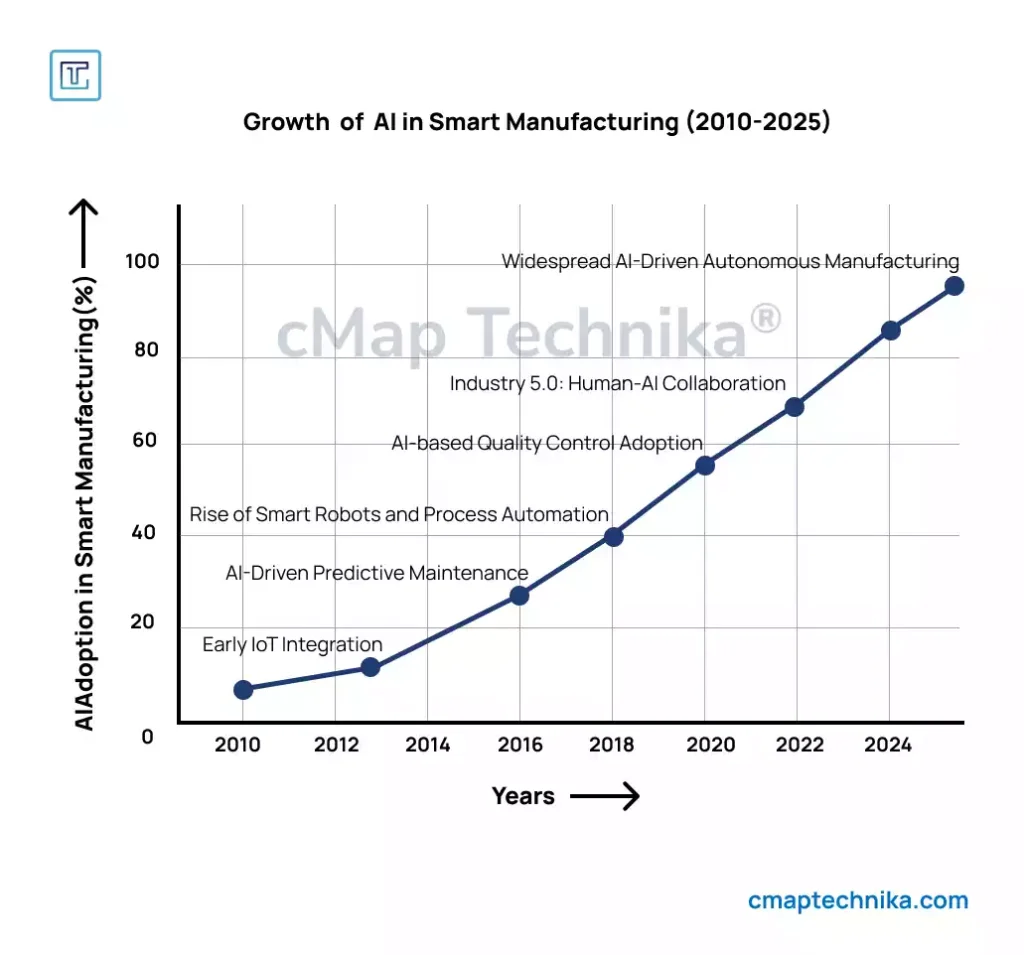

The manufacturing industry is undergoing a profound transformation driven by the rapid adoption of artificial intelligence (AI) and machine learning (ML). Smart manufacturing, a key pillar of Industry 4.0, leverages AI and ML to optimize production processes, enhance product quality, and minimize downtime. Traditional manufacturing models relied heavily on human intervention, reactive maintenance, and manual quality control, often resulting in inefficiencies and increased operational costs. AI and ML are changing this landscape by enabling real-time decision-making, predictive maintenance, and automated process optimization.

This white paper explores how AI and ML are driving the next wave of innovation in smart manufacturing, focusing on predictive maintenance, process automation, and quality control. Through detailed analysis, real-world examples, and industry insights, it highlights the strategic advantages and challenges associated with AI-driven manufacturing.

1. The Role of AI and ML in Smart Manufacturing

AI and ML have become foundational technologies in smart manufacturing due to their ability to analyze large data sets, identify patterns, and make autonomous decisions. By integrating AI and ML into manufacturing ecosystems, companies can achieve higher operational efficiency, improved product quality, and enhanced flexibility.

1.1 Data-Driven Manufacturing

AI and ML thrive on data. Smart manufacturing environments generate vast amounts of data from sensors, machines, production lines, and supply chains. AI algorithms analyze this data to identify inefficiencies, predict equipment failures, and suggest corrective actions.

- Real-Time Monitoring – AI-powered systems continuously monitor production lines and machinery performance to detect anomalies and prevent malfunctions.

- Predictive Insights – Machine learning models predict demand fluctuations, equipment breakdowns, and production bottlenecks based on historical data and real-time inputs.

- Automated Decision-Making – AI systems make real-time adjustments to production parameters, optimizing efficiency and reducing waste.

For example, manufacturers like Boeing and Airbus have integrated AI-powered predictive analytics into their production lines. AI algorithms detect subtle variations in material quality and machine performance, helping engineers make immediate adjustments, reducing waste, and improving overall product consistency.

1.2 Enhancing Operational Flexibility

AI and ML enable manufacturers to respond quickly to changes in market demand, raw material availability, and production constraints.

- Adaptive Manufacturing – AI-driven systems adjust production schedules and resource allocation based on real-time data.

- Dynamic Supply Chains – ML algorithms optimize supply chain management by predicting material shortages and adjusting procurement strategies.

- Customizable Production – AI enables mass customization by adjusting machine settings based on customer specifications.

In the automotive sector, companies like Tesla and BMW have deployed AI-driven adaptive manufacturing models. These systems adjust production speed and resource allocation based on customer demand and supply chain disruptions, reducing lead times and improving cost efficiency.

2. AI-Driven Predictive Maintenance

Predictive maintenance is one of the most impactful applications of AI in manufacturing. Traditional maintenance models rely on scheduled servicing or reactive repairs, often leading to unnecessary downtime or unexpected failures. AI-driven predictive maintenance transforms this approach by anticipating equipment issues before they occur.

2.1 How Predictive Maintenance Works

AI-powered predictive maintenance systems use data from IoT sensors, machine logs, and historical performance data to forecast equipment health and recommend maintenance actions.

- Data Collection – Sensors gather data on vibration, temperature, pressure, and operational speed.

- Anomaly Detection – AI algorithms detect deviations from normal operating conditions, signaling potential failures.

- Failure Prediction – ML models predict the time and nature of equipment failures, allowing proactive intervention.

- Maintenance Optimization – AI-driven systems recommend the most cost-effective repair strategies and spare part requirements.

For instance, General Electric (GE) uses AI to monitor aircraft engines in real-time. AI systems predict when critical components will fail, allowing GE to conduct preemptive maintenance and avoid costly flight disruptions.

2.2 Benefits of Predictive Maintenance

- Reduced Downtime – AI identifies issues early, minimizing production interruptions.

- Lower Maintenance Costs – Targeted repairs and optimized maintenance schedules reduce service expenses.

- Extended Equipment Life – Early detection of issues prevents excessive wear and damage.

- Enhanced Safety – Predictive maintenance prevents sudden breakdowns that could compromise worker safety.

2.3 Case Example

Siemens deployed an AI-based predictive maintenance system across its power plant equipment. The system analyzed data from 500+ sensors, reducing unplanned downtime by 30% and increasing operational efficiency by 20%. The AI platform provided real-time alerts, allowing engineers to address issues before they escalated.

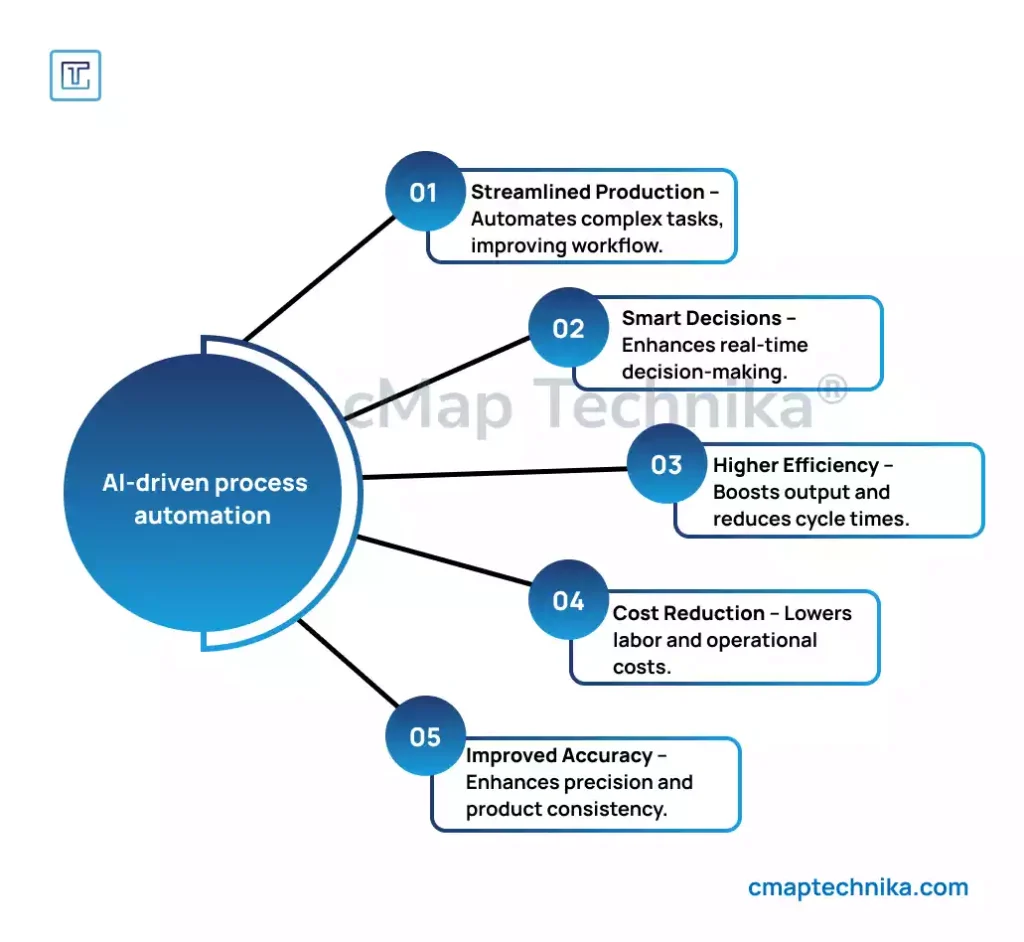

3. AI-Enabled Process Automation

AI-driven process automation enhances production efficiency by minimizing human intervention and optimizing resource utilization. Automation powered by AI can handle complex, repetitive tasks while adapting to changes in production requirements.

3.1 Types of AI-Driven Automation

- Robotic Process Automation (RPA) – AI-powered robots handle assembly, welding, and packaging processes with precision.

- Cognitive Automation – AI systems use natural language processing (NLP) and machine vision to manage quality inspection and defect identification.

- Adaptive Scheduling – AI dynamically adjusts production schedules to accommodate shifting demand and resource constraints.

- Material Handling – AI-driven robots automate material transport and inventory management.

3.2 Advantages of AI-Driven Automation

- Increased Throughput – Automated systems operate continuously without human fatigue, increasing production capacity.

- Higher Accuracy – AI-powered robots achieve higher precision and consistency than human workers.

- Labor Optimization – Human workers are freed from repetitive tasks and reassigned to higher-value functions.

- Cost Efficiency – Automated systems reduce labor costs and improve operational consistency.

3.3 Case Example

Tesla uses AI-powered robots in its Gigafactories for automated battery production. The AI systems continuously adjust the speed and pressure of assembly lines, increasing production efficiency by 25% while maintaining high product consistency.

4. AI-Driven Quality Control

Maintaining consistent product quality is a critical challenge in manufacturing. AI and ML improve quality control by identifying defects in real-time, analyzing root causes, and recommending corrective actions.

4.1 AI-Powered Quality Inspection

AI-based computer vision systems and ML algorithms are used to analyze product images, identify defects, and classify issues.

- Machine Vision – AI-based cameras inspect products for surface defects, color variations, and misalignment.

- Root Cause Analysis – ML models analyze defect patterns to identify underlying process failures.

- Automated Corrections – AI systems adjust machine settings and process parameters to prevent recurring issues.

- Production Consistency – AI ensures that quality standards are consistently met across multiple production lines.

4.2 Benefits of AI-Driven Quality Control

- Higher Yield Rates – Early defect detection reduces waste and rework costs.

- Improved Customer Satisfaction – Consistent product quality enhances brand reputation.

- Continuous Improvement – AI systems learn from quality data, continuously refining inspection accuracy.

4.3 Case Example

Foxconn uses AI-powered machine vision for real-time quality inspection on its assembly lines, reducing defect rates by 40% and improving production speed by 20%.

5. Strategic Recommendations

To maximize the benefits of AI and ML in smart manufacturing, companies should follow a structured approach:

- Invest in Scalable Infrastructure – Build AI-compatible production lines and integrate IoT-enabled systems.

- Adopt a Phased Rollout – Begin with pilot projects to assess AI performance and refine strategies.

- Develop AI Talent – Upskill the workforce to manage and maintain AI systems.

- Strengthen Data Governance – Establish protocols for data quality, security, and access.

- Partner with Technology Providers – Collaborate with AI solution providers to accelerate implementation.

Conclusion

AI and machine learning are driving a new era of efficiency and innovation in smart manufacturing. From predictive maintenance to automated quality control, AI enhances production accuracy, reduces costs, and minimizes downtime. While challenges related to data integration, investment, and workforce adaptation remain, the long-term benefits of AI-driven manufacturing are substantial. Manufacturers that strategically invest in AI and ML capabilities will gain a competitive edge in an increasingly complex and fast-paced global market.