Introduction

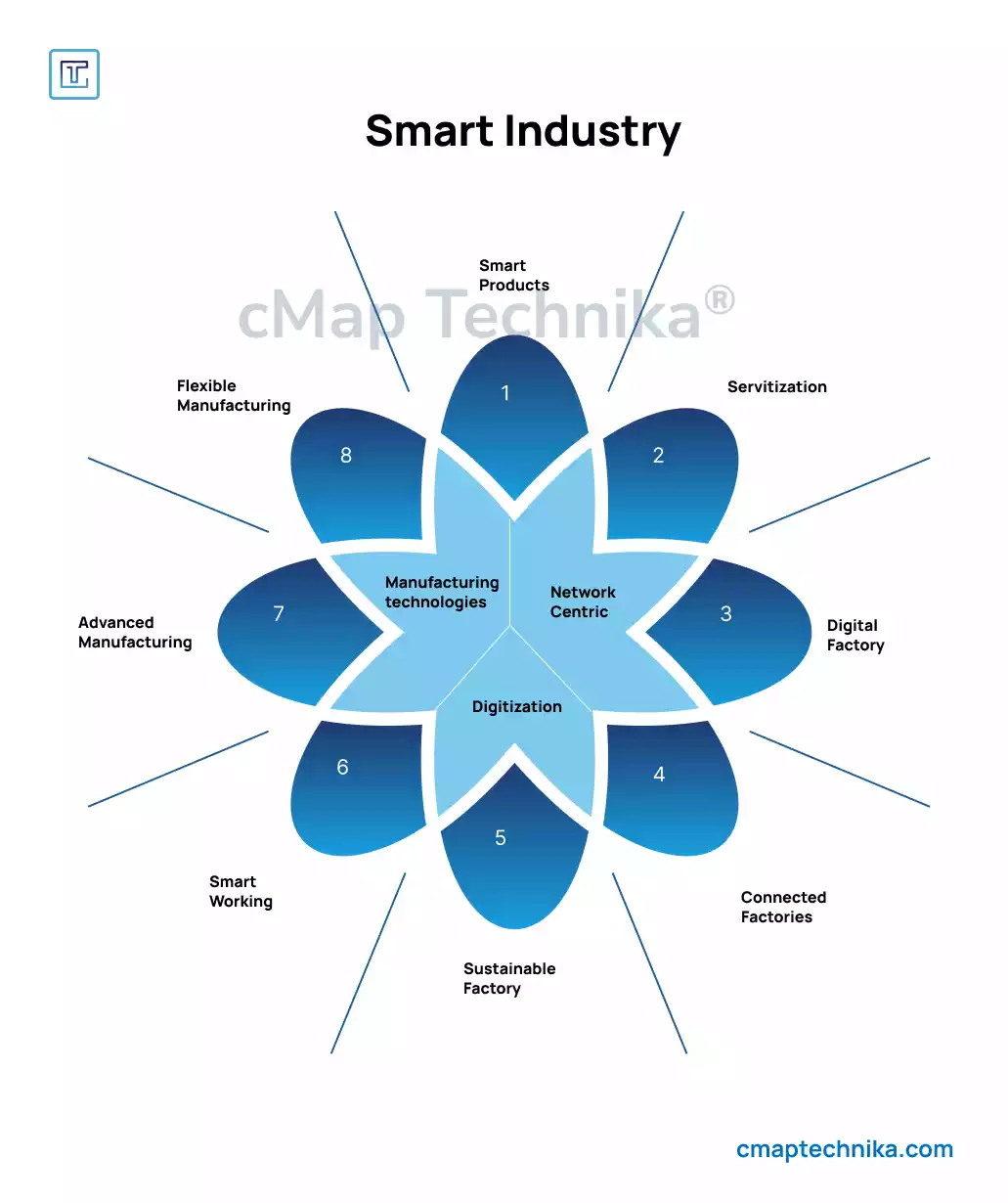

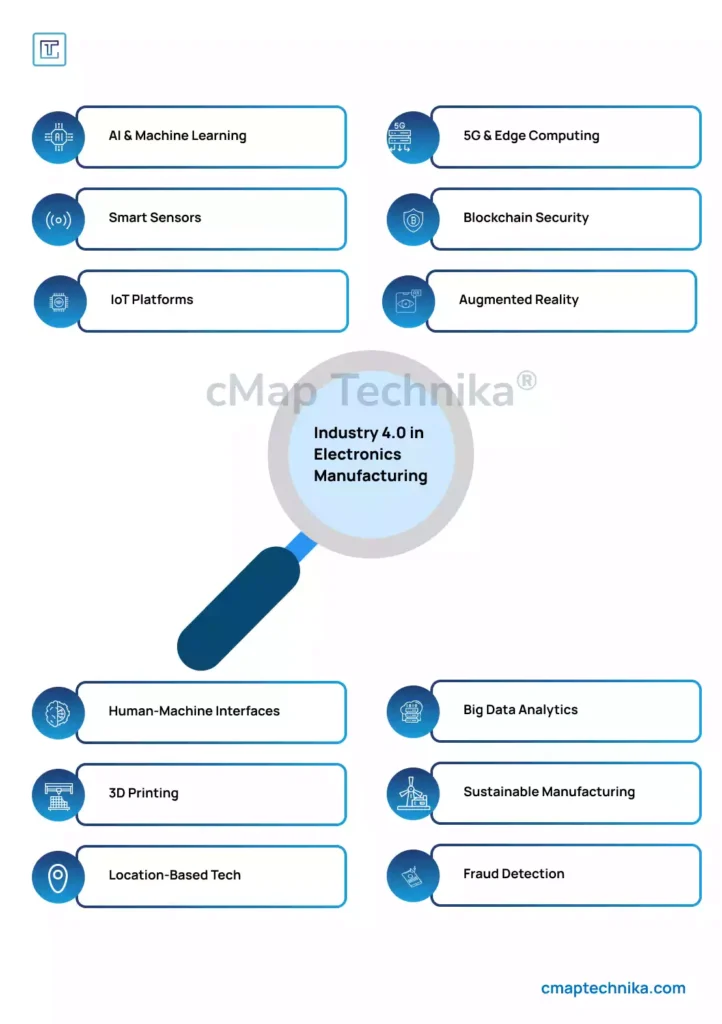

The electronics manufacturing industry is undergoing a profound transformation driven by smart factories, the Internet of Things (IoT), and automation. As global demand for high-quality, cost-effective electronic products grows, manufacturers are integrating Industry 4.0 technologies to enhance efficiency, reduce waste, and improve product quality.

This article explores how smart manufacturing consulting can help electronics companies adopt digital solutions, implement automation, and optimize production processes to stay competitive in an evolving market.

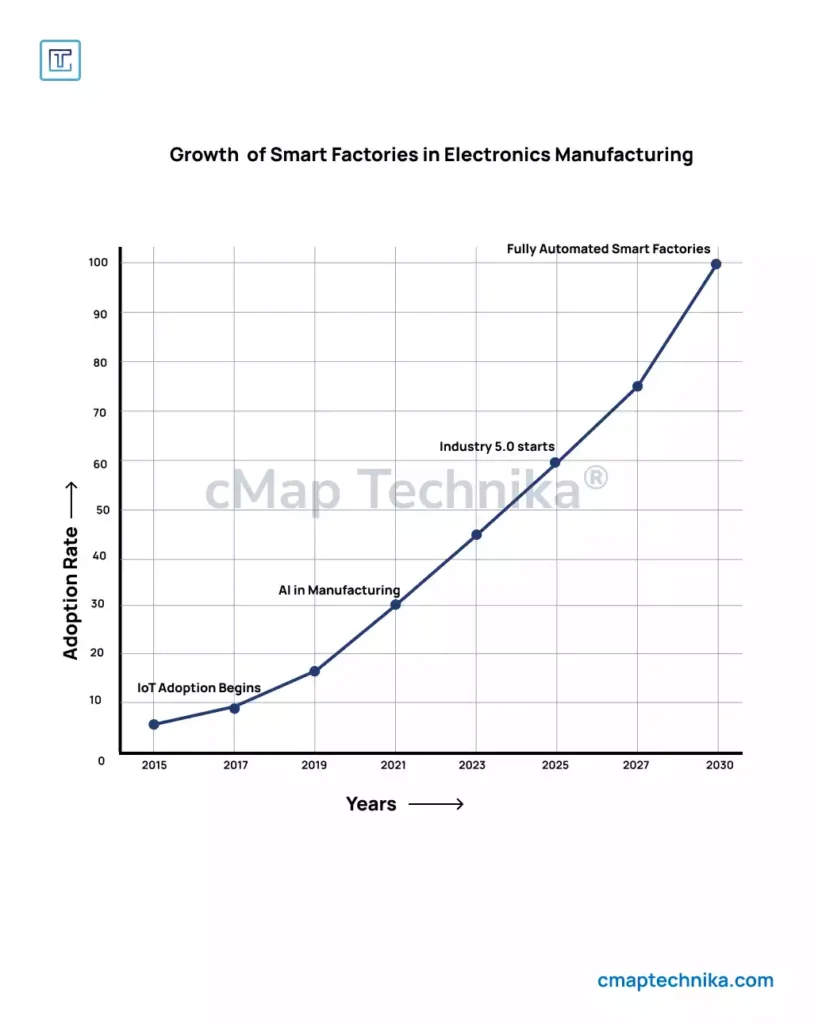

The Rise of Smart Factories in Electronics Manufacturing

A smart factory leverages real-time data, AI-driven decision-making, and autonomous systems to enhance productivity. Unlike traditional manufacturing, which relies on manual processes and isolated automation, smart factories integrate advanced sensors, cloud computing, and AI-powered analytics to enable end-to-end digitalization of production.

Key Features of Smart Factories:

- Data-Driven Operations – Continuous monitoring of production lines using IoT sensors.

- Predictive Maintenance – AI-driven insights reduce downtime by forecasting machine failures.

- Automated Quality Control – AI-based inspection systems ensure defect-free production.

- Flexible Production Lines – Smart robots and automation allow quick adaptation to new product designs.

- Energy Optimization – Smart grids and energy-efficient systems reduce carbon footprints.

Real-World Example:

Samsung, a leader in electronics manufacturing, has implemented AI-powered production analytics across its semiconductor plants. By integrating real-time machine learning models, they have optimized chip production and minimized defects, leading to increased yield and efficiency.

Role of IoT in Electronics Manufacturing

The Internet of Things (IoT) has emerged as a game-changer, enabling manufacturers to create interconnected ecosystems where machines, devices, and workers seamlessly collaborate.

Benefits of IoT in Manufacturing:

- Real-Time Monitoring – Sensors track production metrics like temperature, pressure, and humidity to maintain optimal conditions.

- Supply Chain Visibility – IoT-enabled tracking systems improve inventory management and logistics efficiency.

- Remote Monitoring & Control – Operators can adjust machine parameters remotely, reducing human intervention.

- Enhanced Safety – Smart wearables alert workers to potential hazards, improving workplace safety.

Case Study:

Foxconn, a global electronics manufacturer, uses IoT-enabled predictive maintenance systems across its assembly lines. These systems detect anomalies in real time, reducing machine downtime by 30% and improving production efficiency.

The Power of Automation in Electronics Manufacturing

Automation in electronics manufacturing is evolving from simple robotic arms to AI-powered autonomous systems that make decisions without human intervention.

Key Automation Technologies:

- Robotic Process Automation (RPA) – Reduces human errors and speeds up repetitive tasks like component placement.

- Collaborative Robots (Cobots) – Work alongside humans to handle precision assembly tasks.

- AI-Driven Visual Inspection – Identifies defects in PCBs and semiconductor wafers with high accuracy.

- Autonomous Guided Vehicles (AGVs) – Automate material transport, reducing bottlenecks in warehouses.

- Digital Twins – Simulate production processes in a virtual environment before physical implementation.

Example:

Intel’s automated semiconductor fabrication plants use AI-driven wafer inspection systems, reducing defect rates and enhancing production yield. By deploying machine learning models, Intel has improved wafer throughput by 15% while reducing material waste.

Smart Manufacturing Consulting: Enabling Digital Transformation

For manufacturers looking to transition to smart factories, smart manufacturing consulting services provide tailored solutions to integrate IoT, AI, and automation effectively.

How Smart Manufacturing Consulting Helps:

- Technology Assessment – Identifies the best digital tools based on business needs.

- Digital Roadmap Development – Crafts a step-by-step plan for Industry 4.0 transformation.

- System Integration – Ensures seamless connectivity between IoT devices, AI software, and existing infrastructure.

- Cybersecurity Implementation – Protects industrial networks from cyber threats and data breaches.

- Workforce Training – Equips employees with the skills needed to operate and maintain smart systems.

Example:

A mid-sized PCB manufacturer struggled with high defect rates and slow production cycles. By adopting smart manufacturing consulting, they implemented AI-driven defect detection and predictive maintenance, reducing defects by 40% and increasing throughput by 20%.

Challenges in Implementing Smart Manufacturing

While the benefits of smart factories are substantial, electronics manufacturers face key challenges during digital transformation:

Common Barriers:

- High Initial Investment – Upfront costs for IoT devices, AI systems, and automation tools can be significant.

- Integration Complexity – Legacy systems may not easily interface with modern smart technologies.

- Cybersecurity Risks – Increased digital connectivity introduces vulnerabilities in data security.

- Workforce Resistance – Employees may resist automation due to fear of job displacement.

- Data Overload – Managing vast amounts of sensor data requires advanced analytics capabilities.

Overcoming the Challenges:

- Phased Implementation – Start with pilot projects before scaling up.

- Hybrid Models – Combine traditional manufacturing methods with incremental digital upgrades.

- Strong Cybersecurity Frameworks – Implement multi-layered security measures to protect data integrity.

- Reskilling Programs – Train workers in new digital skills to complement automation.

Future Trends in Electronics Manufacturing

The future of electronics manufacturing will be shaped by emerging technologies that enhance efficiency, sustainability, and customization.

Key Trends to Watch:

- AI-Driven Decision Making – AI-powered analytics will optimize supply chains and production lines.

- 5G & Edge Computing – Faster connectivity will enable real-time data processing at the production floor.

- Sustainable Manufacturing – Green technologies will reduce carbon footprints and promote circular economy practices.

- Hyper-Personalization – AI and smart robotics will enable mass customization of electronic products.

- Blockchain for Supply Chains – Ensuring transparency and security in component sourcing and logistics.

Example:

Tesla’s Gigafactories use AI-driven material planning and blockchain-based supply chain tracking to ensure transparent sourcing of lithium-ion battery materials while reducing waste.

Conclusion

The digital revolution in electronics manufacturing is redefining how products are designed, produced, and delivered. Smart factories, IoT, and automation are no longer optional—they are essential for staying competitive in a fast-paced global market.

By leveraging smart manufacturing consulting, electronics manufacturers can develop scalable, efficient, and future-proof solutions that enhance productivity, reduce costs, and ensure high-quality output.As we move towards Industry 5.0, the synergy between human expertise and digital intelligence will drive the next phase of innovation and sustainability in electronics manufacturing.